Thank you for your loyal and continued support throughout 2023.

The team wish you a very Merry Christmas and a safe, Happy New Year.

Please see link to our full order and delivery cut off dates.

Posted in:The webinar will focus on accurate quantity take offs for Potters aluminium partitions and cover minimum requirements for accurate take offs.

Working through some typical door\window examples.

Key considerations and things that are often overlooked.

Posted in:This year TRACKLOK Ltd turns 10 years old! What a ride and what an accomplishment — they have taken the learning from the Christchurch seismic sequences and incorporated them into practical seismic solutions used throughout New Zealand, Australia, and USA daily.

TRACKLOK Ltd continues to be dedicated to improving building practices through logic and compliance. The TRACKLOK, DEFLOK and GRIDLOK range of products have been developed to address the risk of non-structural failure in commercial buildings.

These pre-engineered solutions are designed for architects, structural engineers, and construction professionals.

Non-structural failures account for a significant portion of repair costs after an earthquake, often reaching 70% to 80%. By installing non-structural restraints during construction, these risks can be significantly reduced. The cost of incorporating restraints at the outset is typically 3% to 5% of the total build costs, while retrofitting is far more expensive.

TRACKLOK focuses on securing walls, while GRIDLOK is designed for bracing ceilings. The range applies logic, innovation, and best practices to improve building resilience and mitigate the risk of non-structural failure. Compliance with building codes, such as NZ/AUS Building Code B1 Structure, AS/NZS 1170, and AS/NZS 2785, ensures safety and performance requirements are met.

While this is true for New Zealand, the same requirement exists in the Australia and even more stringent requirements exist for the USA. The inclusion of these products into larger markets abroad has allowed TRACKLOK Ltd to gain significant certifications in the USA. Primarily HCAI OPM’s for the California health sector, standards that are the most stringent in the world. This achievement allowed DSA’s education projects to specify TRACKLOK products for their needs.

Seismically bracing non-structural elements not only protects human lives but also support business continuation. Interruption to business operations result in significant time and financial losses. By implementing TRACKLOK, DEFLOK and GRIDLOK, you minimise downtime and demonstrate a commitment to risk mitigation, enhancing business continuity. And ensuring you’re future-ready.

Insurance considerations are also essential as insurers evaluate safety measures when determining coverage and premiums. Proactively installing TRACKLOK, DEFLOK and GRIDLOK shows your commitment to risk reduction.

TRACKLOK Ltd collaborates with like-minded industry leaders and actively participates in the following organisations:

Together, we strive for a better industry governed by sensible codes of practice.

Choose TRACKLOK seismic bracing solutions to mitigate non-structural failure risks, enhance building resilience, and ensure a safer commercial environment. Embrace logic, innovation, and best practices for a secure future in construction.

With 10 years of design, development, testing and real world implementation across the world, trust TRACKLOK to ensure you’re future-ready.

Posted in:Plus tag us on social media wearing the jacket onsite with Tracklok product and receive a free hoodie!

Products include TRACKLOK® DEFLOK® GRIDLOK®.

Exclusive to Potter Interior Systems trade account holders.

Limited stock of puffer vest available, while stocks last.

Limit 5 per transaction. Standard terms and conditions of sale apply.

Reward valid from 1st August – 12 September 2023.

Potter Interior Systems Standard Terms and Conditions of Sale apply.

View the Tracklok range here

Posted in:Potter Interior Systems is committed to supporting your professional development and keeping you up-to-date with the latest industry knowledge. We are excited to announce that we have partnered with the New Zealand Institute of Architects, to offer accredited CPD activities and training.

These courses have been curated to provide you with valuable insights and knowledge that are relevant to your architectural profession.

We look forward to assisting you in your journey towards excellence in architectural design and construction.

Please join us for an evening of knowledge-sharing, product demonstrations, networking opportunities and exclusive warehouse tours.

Featured products and solutions:

– Rondo Donn and Rondo Key Lock ceiling systems

– Tracklok seismic bracing solutions

– Ceiling Tiles: Explore the AMF range

– Perforated Plasterboard Decorative Ceilings

– Passive Fire Stopping Systems

– Custom Wall Solutions – Whiteboards, Pinboards

– Aluminium Systems – the latest advancements

24 AUGUST 4.30-6.30PM

POTTER INTERIOR SYSTEMS

393 CHURCH STREET,

PENROSE

When it comes to collaborative workspace tools, we’ve come a long way in the last century. When we think of such tools in 2023, the first things that come to mind are usually digital applications – video conferencing software like Zoom, instant messaging platforms like Slack, and a host of CRM systems to keep things running smoothly.

Many of these platforms are relatively new, and were born from the rapid evolution of digital products that went before them – so it’s something of a remarkable feat when the essence of an undisputed cornerstone of digital collaboration remains mostly the same as it was at its inception, like email.

It’s arguably even more impressive when collaborative tools remain relevant throughout the decades up until the present day, all while being completely tangible, analogue products. This is the case with whiteboards and other collaborative writing surfaces: from their invention in the 1950s until today, they maintain their status as a mainstay in classrooms, universities, retail spaces and workplaces.

This is partly due to, not despite, changes in technology, says Potter Interior Systems Sales and Development Manager Rachael Marsh. “With technology throughout work environments and modern classrooms, writing surfaces are, and will remain, one of the most important tools.”

This is in large part due to the enduring appeal of physically writing down thoughts and ideas in educational and collaborative settings.

“Cognitive mapping research has shown that the physical process of writing and diagramming helps people learn and recall information,” says Marsh. “Using a writing surface is both tactile and visual, so the act of writing and drawing engages the user physically and mentally, which boosts learning.

“Making proper use of vertical space with a whiteboard surface can facilitate group work, increase engagement, foster innovation and make thinking visible. Incorporating writing surfaces into meeting rooms or classrooms allows individuals to brainstorm, communicate and share ideas with others.”

As one of the leading manufacturers of whiteboards for the commercial construction market throughout New Zealand, Potter has seen firsthand how changes in the market have necessitated rethinking how we use whiteboards – hence the genesis of products like its interactive whiteboards.

This product is a combination of a projection screen and a whiteboard, enabling for productivity by screen mirroring, while maintaining the ability to use the board as a writing surface. Specifically designed to reduce light reflectivity, it remains an easy-clean and scratch-resistant surface – like all of Potter Interior Systems’ other whiteboard products.

Each whiteboard is manufactured with certified, VOC-free porcelain on a steel writing surface, affixed to an aluminium backing. The premium porcelain ensures it’s not only an excellent surface to write, it’s also resistant to scratches and stains. Each has a 25-year surface guarantee, multiple installation options, and the ability to use magnetic products and accessories.

One of the company’s most popular products is its Edgeline offering, an everyday whiteboard whose frame allows for two different board thicknesses, providing flexibility for different installation methods. For especially large rooms and walls, multiple boards can be connected with a slimline H-jointer – resulting in almost seamless joints between different boards and a wall-to-wall writing surface.

Then there are the ‘hybrid’ products – whiteboards that blend their functionality with other similarly useful items. This includes the pin board + whiteboard combination offering, which offers a 50/50 merging of the two types of boards for ultimate convenience. Customers can choose from a fabric range that includes over 30 different colours.

The Whiteboard Cabinet Slider is an entire furniture piece that features a slidable whiteboard at the top, with storage in the cavities behind, as well as more cabinet storage beneath the sliding boards.

“A whiteboard cabinet is an excellent way to optimise your storage space within a room,” says Marsh. “We supply the highest quality frames and sliders that have been favourites of teachers for many years. The system is designed specifically for hard-working environments.”

With the ever-enduring mobile, wheeled boards rounding out their large whiteboard offering, the formidable range covers almost all bases – and it remains dedicated to enhancing productivity in workspaces and educational settings around the country.

Introducing the Potter Interior Systems Passive Fire Solutions Finder, revolutionising the way you discover and select the perfect fire stopping products and solutions for your projects. We understand the importance of efficiency, reliability, and safety when it comes to passive fire protection, and our innovative search function is designed to meet your exact needs.

With our user-friendly and intuitive tool, located conveniently under the ‘Search Solutions’ tab on our home page, finding the right passive fire solutions has never been easier. Our team of experts has meticulously developed this tool to provide you with a seamless and effortless experience.

Our search function offers two efficient methods to explore our extensive range of fire stopping solutions: criteria-based search and keyword search.

At Potter Interior Systems, we are committed to delivering exceptional passive fire protection solutions. We understand that every project is unique, and that’s why our Passive Fire Solutions Finder is designed to provide you with tailored options that meet your specific needs. Say goodbye to tedious manual searches and embrace the future of fire stopping product selection.

Visit our website today and experience the ease and efficiency of the Potter Interior Systems Passive Fire Solutions Finder.

Your search for the perfect fire stopping solution starts here.

Since 2016 Potters aluminium partition suites have proudly carried the Declare label, which is a nutrient label for the building industry, ensuring consumers have all the information about the products they buy.

Declare is part of the International Living Future Institute’s (ILFI) suite of programs that catalyse a socially just, culturally rich and ecologically restorative future. This trusted public database and product labelling program answers 3 key questions:

Material selections and product transparency have emerged as increasingly crucial factors in the regenerative building movement, circular economy and human and environmental health, through design, specification, product manufacturing and supply chain transparency.

WHAT IS A DECLARE LABEL?

A Declare label displays compliance (or otherwise) with the stringent criteria of the Living Building Challenge (LBC) Materials Petal and Healthy Interior Performance Imperative, which helps specifiers and clients make informed choices for healthier buildings. They can be likened to nutritional labels that make understanding product ingredients easier.

Demand for materials transparency and specifier interest in the makeup of products is increasing, helping to shift the supply chain. Transparency programs like Declare build knowledge and facilitate the transition to a healthier built environment.

Posted in:As the leading manufacturer of whiteboards and related products in New Zealand, this comprehensive manual serves as a definitive guide to the specifications, features, and applications of our diverse range of commercial whiteboards, pinboards, notice boards, mobile boards, glass boards, cabinet sliders, dividers, displays, and acoustic solutions.

Established in 1966, Potters has a proud legacy of supplying Kiwi classrooms, universities, retailers, and workplaces with high-quality whiteboards that meet the specific needs of their customers.

Our commitment to delivering exceptional products has made them the preferred choice for designers seeking unique and customized solutions. “We are proud to be the market leader with our range of products that meet the needs of the modern workplace,” said Rachael Marsh, Sales + Development Manager. “Our products are designed to deliver the perfect solution for an innovative working and learning environment.”

The new manual provides an overview of each product category, highlighting key features, technical specifications, and application scenarios. It offers architects, designers, and other industry professionals a detailed understanding of the possibilities and advantages of integrating Potters’s products into their projects.

The manual also serves as a valuable resource for customers, empowering them to make informed decisions when selecting the ideal whiteboard or accessory for their specific requirements.

The release of the Product Specification Manual represents a significant milestone for Potters, as it reaffirms our position as an industry leader and exemplifies the dedication to delivering exceptional products backed by unparalleled customer support.

Click Here to download the new product manual.

Posted in:In the wake of the COVID-19 pandemic, maintaining a high level of hygiene in commercial spaces has become a paramount concern. Among the various surfaces within these spaces, ceiling tiles often go unnoticed but play a crucial role in overall hygiene.

Commercial spaces, such as offices, retail stores, hospitals, and educational institutions, are frequented by a large number of people daily. Ensuring a hygienic environment is essential to prevent the spread of germs, bacteria, and viruses. Maintaining hygiene not only promotes the wellbeing of occupants but also enhances their productivity and overall satisfaction.

Ceiling tiles are an integral part of the building envelope, contributing to aesthetics, acoustics, and insulation. However, they are often overlooked when it comes to hygiene. Traditional ceiling tiles may accumulate dust, mould, and bacteria over time, posing a risk to indoor air quality and occupant health. Therefore, adopting innovative solutions specifically designed for enhanced hygiene is crucial.

Modern ceiling tile solutions are available that offer advanced hygiene features to address the challenges faced in commercial spaces. Here are some key characteristics and benefits:

It is important to ensure that the selected ceiling tiles comply with relevant regulations and certifications in New Zealand. Considerations such as fire resistance, acoustic performance, and sustainability should also be evaluated alongside hygiene features.

Installing hygiene-focused ceiling tiles is just one aspect of promoting cleanliness in commercial spaces. Regular cleaning and maintenance routines, along with proper ventilation systems, should be implemented to achieve optimal hygiene standards.

In the post-pandemic era, maintaining a high level of hygiene in commercial spaces is of utmost importance. Incorporating specialised ceiling tiles with advanced hygiene features can significantly contribute to a cleaner and safer environment for occupants.

Posted in:What’s above your head can make a big impact within a space and black ceilings have become a popular choice for restaurants, offices, law firms and medical facilities.

Extremely versatile, black ceilings are a great way to add dimension and contrast to your space making a room appear larger and ceilings taller without spending too much money on expensive renovations or furniture upgrades.

The ceiling plays a major role in how a space’s style and mood come together, with black being ideal for creating a modern, sophisticated look.

When to consider ceiling black ceiling tiles:

From aesthetics to performance, Potters dedicated specification team can help architects and designers to provide the perfect solution.

Posted in:Good building acoustics are becoming increasingly important in today’s architecture and design as it supports the overall atmosphere created for users. Being able to control noise and sound also has a great impact on health and wellbeing, along with an increase in productivity.

Minimising the transmission of noise from one space to another while controlling the sound itself can be very important for all types of offices, education, health care and public venues – the fact is, good acoustics are important in almost any setting.

Benefits of Acoustic Treatments

Whether we’re conscious of it or not, we are always listening to the environment around us. The sounds we take in impact our ability to perform, interact and thrive. For this reason, we need to create an acoustic environment that is as comfortable as possible.

An acoustic treatment seeks to improve the sound transmission from one space to another by absorbing the sound waves within a room. Acoustic Ceiling Tiles are an easy and effective way to reduce the echo in a noisy environment, and our range of AMF Thermatex Acoustic suspended ceiling tiles provide:

Explore and discover our collection that will bring the perfect balance of acoustic performance and design, creating the optimum environment for your next project.

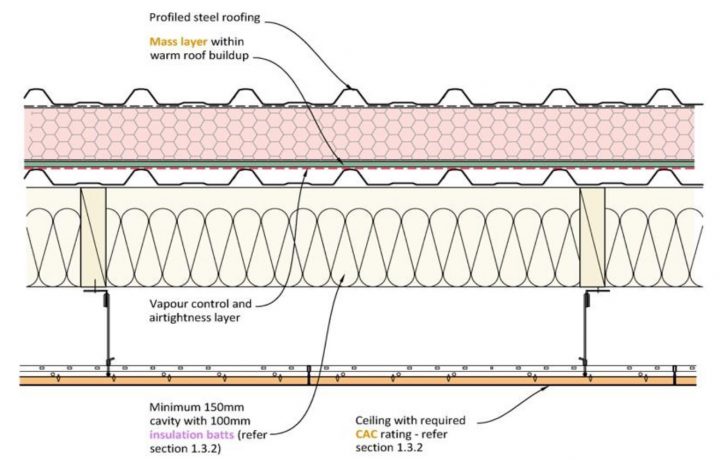

Posted in:HVAC Service Bundles: Saving Space and Making Compliance Easier.

Specifying multi-service bundles which have been tested for compatibility with acoustic lagging and thermal insulation can help simplify compliance.

The NZBC continues to evolve. With each update we see it call for greater thermal values on mechanical/HVAC systems. Whilst this has obvious performance benefits to the system on how economical it performs, there are some knock-on effects in other areas of building compliance relating to fire.

When it comes to passive fire treatment of pipes and cables passing through fire rated walls and floors, the New Zealand Building Code refers to two options when it comes to compliance. The first being identical with a prototype assembly of the service, building element and protection method which has been tested in accordance with AS4072.1 and AS1530.4 and has achieved the required FRR or differ from a prototype assembly of the service, building element and protection method in accordance with Section 4 of AS4072.1. In basic terms the first option means it must be identical to the tested system, the second option will generally refer to variations from a tested system that have been documented by an IANZ or NATA approved laboratory based on one or more tests whereby the scope allows for variations from the original tested system.

How do increased thermal values on mechanical piping affect the firestopping you might ask? If using the first path to compliance, thicker lagging on a copper pipe than was originally tested would mean that the system once used to firestop this pipe may no longer be compliant as the lagging may differ to the original tested system. In the case of the second option of compliance, thicker lagging on the copper pipes may still be ok if the AS4072.1 compliant fire assessment uses words like “minimum thickness” or refers to a specific maximum thickness which is preceded by words like “up to”. This is an important detail to look out for when specifying a system.

What else can be affected by new thermal values? We have seen more and more different types of materials being used for lagging on mechanical copper pipes. As the call for higher R-Values continues, manufacturers are looking for efficient ways to achieve performance. Black nitrile rubber products are no longer the only options with many other brands entering the market with materials such as cross-linked polyolefin. When it comes to the path of compliance, what does the test report or fire assessment refer to when it comes to the lagging type? Does it refer to a specific brand? Or does it refer to specific performance requirements of the lagging type? Look out for systems that refer to multiple brands or materials with specific performance criteria for greater versatility.

The next issue to arise for higher R-Values is related to space. More and more services are running throughout commercial and residential buildings, often the only room for these services to pass from one fire compartment to another is above a door head into an apartment or riser cupboard or passing through a floor slab in a riser shaft. Traditional passive fire treatments have commonly called for each individual pipe or cable to pass through its own aperture and maintain a minimum of 40mm between each aperture. It can become increasing difficult to fit so many services in the one area and maintain the correct separation in these small areas as the lagging is getting thicker, meaning that the diameter of the pipes gets bigger and bigger.

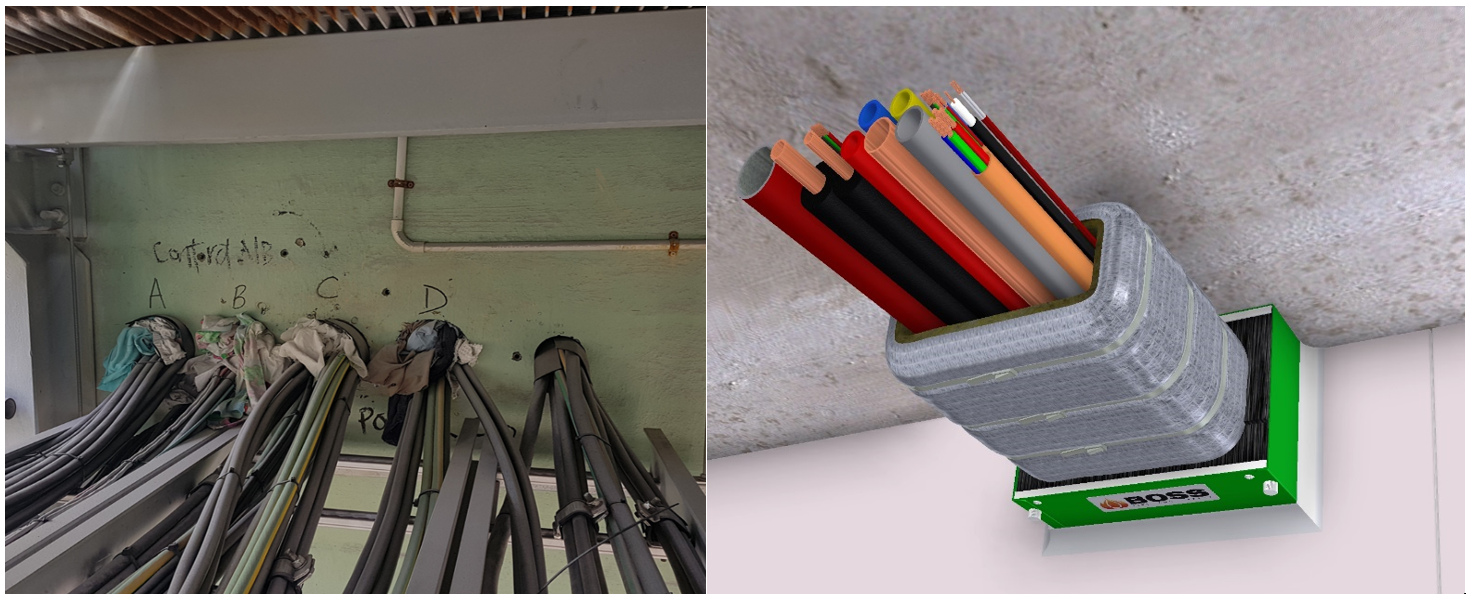

Fortunately, there are a wide range of products that can help resolve these issues. The team at BOSS develop their systems based on years of experience ‘on the tools’. So when it comes to product development they look for versatility and simplicity.

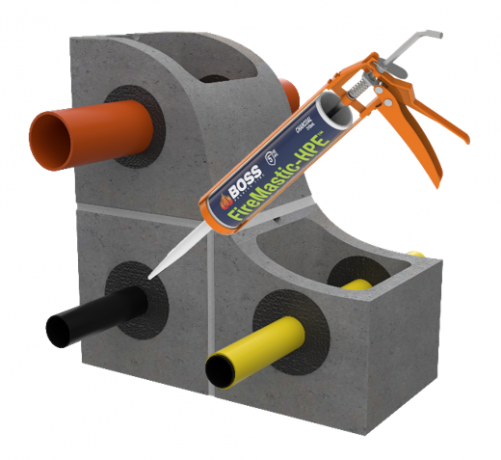

One option is the FireMastic-HPE, a high pressure exerting intumescent fire sealant perfect for mechanical service bundles. For many years the ‘HPE’ has been able to bundle A/C Paircoil with power and control cables, along with a condensate drain or conduit. Recent testing has seen a whole new range of approvals on thicker pipe lagging, different types of pipe lagging and more pipes through the one aperture making it an incredibly versatile fire sealant for mechanical services.

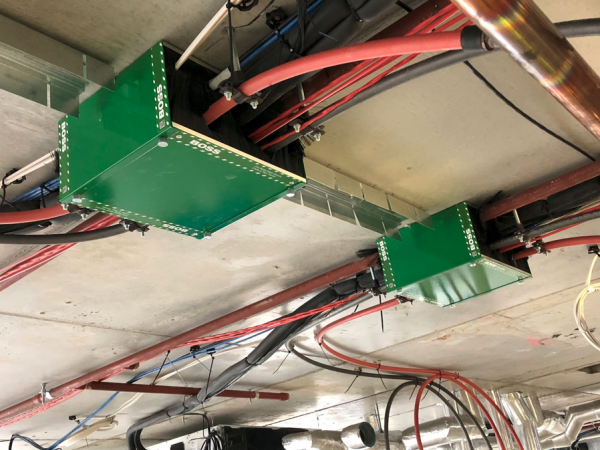

Multi-service transits such as the BOSS FyreBox continue to improve the way multiple services can be treated through one aperture. Not only does the FyreBox enable large bundles of services to all go through one simple device, but the extensive product testing on different types of pipe lagging has seen the range of approved lagging recently increased. Whilst various brands of insulation are directly referred to in the certification it also provides options for lagging types that meet minimum performance criteria. (This comes in handy when lagging manufacturers can often re-brand the same product under a different name and distributer). The BOSS FyreBox certification also generally calls for a minimum thickness of lagging relating to a specific FRL making it easy to maintain compliance with one product across a multitude of systems as pipe lagging thickness varies. Now with larger diameter copper than ever before the BOSS FyreBox continues to provide innovative solutions to common site problems.

Posted in:Potter Interior Systems believe that product transparency is crucial to increasing the availability of healthy products in the marketplace and helping you to make the right choice when designing and specifying your projects.

As specialists in aluminium partition systems Potters recently supplied a seamless mix of partition suites to CBRE Asia Pacific’s new Auckland office.

The result is a contemporary workplace that’s open and relaxed with various break-out spaces to suit different working styles. Working with Stack Interiors, the design process was aligned for sustainability, including locally sourced and sustainable materials.

All Potter Interior Systems aluminium partition suites are proudly designed in New Zealand and carry the Declare label, which is a nutrient label for the building industry, ensuring consumers have all the information about the products they buy.

Declare states where the product is made, if it contains any red list chemicals, it’s end-of-life options and gives confidence that products are non-toxic and safe.

Designed by: Stack Interiors

Constructed by: Alaska Construction + Interiors

Photography: Mark Scowen

Get Your Free Puffer Vest with every 50 Tracklok, Gridlok or Deflok items purchased between July To August 2022 🔥

*Reward valid from 1st July to 31st August.

Exclusive to Potter Interior Systems trade account holders.

Tracklok products include Retro, Timba, Flat, Gaplok, Deflok and Gridlok.

Limited stock of puffer vest available, while stocks last. Limit five per customer.

Potter Interior Systems Standard Terms and Conditions of Sale apply.

View the Tracklok range here

Posted in:In the event of a seismic event, will the specified passive fire treatment need to remain in place ready to work in the event of a fire? Or is the treatment designed to be repaired if it has cracked or moved during the seismic event?

Passive fire and movement aren’t often considered together in one application, yet so often we see requirement for movement in areas of a building that requires firestopping. Treatment of linear gap seals, control joints and penetration seals around services are common areas for passive fire protection. Control joints can often be sealed using fire rated mastics, and larger gaps can be sealed using products like fire rated bulkhead batts, but what if the gap is at a deflection head? Or if the top of a fire rated wall requires movement from ground heave? Are there seismic movement requirements around services?

Deflection head gaps at the tops of walls commonly have up to 20mm movement required for walls to move up and down as concrete floor slabs move and deflect and these scenarios are commonly dealt with using fire rated mastics or sealants. However, we’ve seen gaps in commercial buildings and infrastructure projects require bigger gaps, often due to the ground heave or structures settling over time. Products like BOSS FireStrip-ALX can help in this situation.

Designed to perform as a fire barrier in construction movement joints according to AS1530.4: 2014 and AS4072.1-2005, FireStrip-ALX is elastomeric foam laminated with a graphite based intumescent layered on both sides. It is designed for linear installations in horizontal and vertical applications, with different sizes available to suit different gaps.

Common passive fire treatment for around services like pipes and cables are commonly treated with fire rated mastics and sealants, fire collars, pillows and wraps and whilst some of these products do allow for some movement, they are unlikely to provide large amounts of movement. In the event of a seismic event, will the passive fire treatment need to remain in place ready to work in the event of a fire? Or is the treatment designed to be repaired if it has cracked or moved in the event of a seismic event?

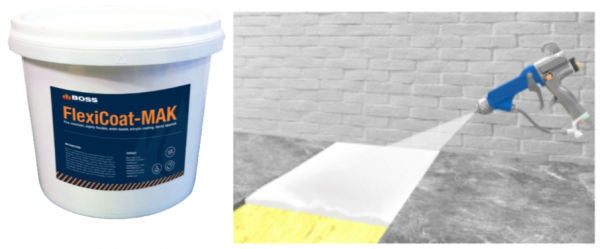

One solution for these application is FlexiCoat-MAK, a system that is tested and approved to AS1530.4:2014 and AS4072.1-2005 to achieve a 2hr fire rating (FRR -/120/120) for apertures in walls and floors up to 1100 x 1100mm or continuous linear gaps seals up to 200mm wide and provide up to 50% movement. Systems like these not only restore the fire compartment, but will also provide movement around services for seismic purposes. The system comprises of a flexible 80kg rockwool 100mm thick base product, which gets coated with a water based elastomeric acrylic coating known as FlexiCoat-MAK, which is suitable for spray, trowel, brush and pouring applications.

These systems are designed for passing through services including steel and copper pipes, steel pipes, large cable bundles and cable trays, and even lagged copper pipes. The system will provide the necessary firestopping requirements and allow for movement from seismic perspective.

Posted in:Potter Interior Systems range of Premium Whiteboards, Pinboards and Noticeboards have been manufactured in New Zealand since 1982. With a proud 40 year history of supplying Kiwi classrooms, universities, workplaces and favoured by designers looking for something unique.

Offering a custom-made solution the whiteboards are manufactured from our Auckland production facility, using the highest quality porcelain, aluminium frames, solid substrates and locally made components.

What sets us apart is the ability to control supply chains to offer guaranteed dates of supply with lower lead times and consistent pricing through some of the following procedures:

Our knowledge and commitment to customer satisfaction has enabled the manufacture of whiteboards to continue at the same pace without delays, resulting in all projects being delivered on time and finished to the highest quality standards.

Speak to Potters today to see how they can design a solution to suit your project’s requirements.

Posted in:We have all heard the terms Fire Rated, Fire Resistant and Fire Retardant. But do they all mean the same thing?

Whilst the words themselves sound similar, and when looking at a dictionary definition, they might sound the same, however in the building industry without some context to a physical test standard and associated performance to a test standard, then they might just be meaningless words.

So, what must you look out for when checking if a fire rating is actually a fire rating? Firstly, we must look at the specific application or building scenario that we need a fire-resistant product for. Relative to the specific building scenario will be a reference in the New Zealand Building Code (NZBC) or the National Construction Code (NCC). In the NZBC and NCC are references to specific New Zealand / Australian Standards that a product will likely need to be tested to with minimum performance criteria.

For the purposes of this article, we will focus on service penetrations that pass-through fire rated building elements such as pipes and cables. For these elements the NCC refers to a Fire Resistance Level (FRL) or Fire Resistance Rating (FRR). This is defined as grading periods in minutes determined in accordance with Schedule 5 for the following criteria: “Structural Adequacy”, “Integrity” and “Insulation” and is expressed in that order shown as numbers separated by a forward slash (/). For example: FRL 120/120/120 would offer 120 minutes structural adequacy, 120 minutes Integrity and 120 minutes Insulation. This testing criteria refers to AS/NZ 1530.4. The current version of this standard is 2014.

When products are tested to AS1530.4:2014, the system or specimen is made up of the building element (wall or floor) and any service passing through that wall or floor (e.g. pipes or cables), and the products and specific manner in which they are installed. This overall system will provide the specific tested performance. The performance criteria refer to the following:

Structural Adequacy refers to the ability of a loadbearing element to maintain stability and adequate loadbearing capacity. The failure criteria of this refers to whether the specimen falls down or it deflects or it deflects by a more than certain amount or by greater than a certain rate. Service penetrations do not have a structural adequacy aspect required and therefore this criterion in the FRR will be shown with a dash. Example -/120/120.

Integrity refers to the ability of an element of construction to resist the passage of flames and hot gases from one space to another. There are a number of ways in which this criterion is measured, however it basically refers to having no openings or gaps occurring in the specimen that would allow flame or hot gases to escape. One form of measurement is the use of a cotton pad which is placed over the gap or opening for 30 seconds to see if it will ignite. If the cotton pad ignites this will be considered a failure at that time. Another failure criteria refers to the observation of flames on the non-fire side for a period greater than 10 seconds. For some more specific applications a gap gauge can also be used.

Insulation refers to the ability of the surface of an element of construction not exposed to the furnace (or non-fire side of the compartment) to maintain a temperature below the specified limits. The specified limit in this case is 180°C above the ambient temperature of the element at the time just before the test begins. For example, if a metal pipe was 20°C just prior to the start of the test, then the failure criteria would be the temperature of the pipe exceeding 200°C. Each specimen has thermocouples placed on and around the specimen in locations specified by the standard. These thermocouples measure the temperature throughout the test.

All of the above criteria are measured in the form of minutes from the start of the test before they exceed the failure criteria. The number is then rounded down to the nearest 30-minute interval. The NCC refers to the most common intervals as 30, 60, 90, 120, 180 and 240 minutes. Even if the time in one performance criteria misses the next interval by only one minute, then that criterion gets relegated back to the earlier interval. As an example, if flaming was to occur around a pipe for more than 10 seconds at 119 minutes it would miss the “2hour” rating of 120 minutes and be pushed back to 90 minutes.

When it comes to the performance of service penetrations, these don’t require a structural adequacy rating and will always be shown with a dash at the start, eg. FRR -/120/120.

A wide range of firestopping products are available that will perform to achieve both integrity and insulation ratings. Products like BOSS FireMastic-300 fire and acoustic sealant are designed for metal pipes and small cable bundles, while High Pressure Exerting Intumescent sealants such as BOSS FireMastic-HPE can also be used for HVAC services, cable bundles and combustible pipes. Other products are designed to treat pipe penetrations. These types of products are ideal for treating small cable bundles, combustible pipes or smaller metal pipes and will achieve FRR’s commonly of up to -/120/120.

But what happens when there are a lot of metal elements that get hot faster? When it comes to uninsulated large steel or copper pipes or metal cable trays filled with large bundles of big power cables, these will generally conduct heat through the penetration faster and transfer it to the no fire side of a wall or floor. In most cases a sealant will not be enough to meet both the integrity and insulation criteria. As an example, a non-insulated 150mm copper pipe treated with sealant alone might achieve an FRR -/120/-.

So how do we get the insulation criteria to perform better? The answer often comes in the form of an insulation blanket or thermal wrap. Products such as the BOSS P40-MAK Wrap and BOSS Thermal Defence Wrap can be used to wrap around a service for a short distance on both sides of a wall or top side only of a floor slab. Depending on the size of the service the wrap might extend 300mm from the building element or up to 600mm. This style of thermal insulating product can increase an insulation rating up to 240 minutes or 4 hours. For example, a metal pipe that might only achieve FRR -/120/30, the addition of the thermal wrap can easily bring this up to FRR -/120/120. It’s important to note that other passive products will form part of the system to aid the integrity rating. For instance, a sealant and wrap might complement each other. The bigger the service or the higher performance rating required will determine the distance in which the service needs to be wrapped.

Posted in:Ceilings play an integral part of every interior space with a seamless connection between design, acoustics and air quality.

AMF Thermatex Acoustic is a mineral fibre ceiling tile designed with both sound insulation and absorption in mind. This is largely thanks to its innovative acoustic fleece, which also helps provide a smooth and modern look.

The Thermatex Acoustic range achieves excellent sound absorption of up to 0.65 αw, and sound insulation values of 40dB. This makes it particularly suited for environments where multiple sources of sound need to be managed, such as retail, offices and showrooms.

The high-quality mineral tiles are produced in a wet-felt tile process that uses natural, sustainable raw materials, including biosoluble mineral wool, perlite, clay and starch.

Contributing to healthy interiors the Thermatex range also helps to increase air quality through low formaldehyde emission levels deemed as best-in-class.

Specialist features include:

To find out more about the AMF Acoustic range of suspended ceiling tiles please see the range here https://potters.co.nz/catalogue/ceiling/mineral-fibre/

Posted in:Every $1000 you spend on eligible Mammoth Insulation products gives you one entry to

Win One of Ten Swanndri Foxton Oilskin Vests.

The promotion will commence on the 02/05/22 and close on 30/06/22.

Customers must have a valid csrconnect account to be eligible to enter.

Eligible Mammoth products include Novahush Ductliner, Novahush Bafflestack,

Novahush Panel Absorber, Novahush Sound Blanket. Exclusive to Potter Interior Systems trade account holders.

Enter now at www.csrconnect.co.nz

See Full Terms + Conditions Here.

Posted in:Plasterboard is typically required on site before plumbers, electricians, fire and HVAC contractors can begin to carry out their works, so what happens when you don’t have the plasterboard?

Keeping a project on schedule has always been one of the key issues with construction. Since the pandemic began this has never been more relevant. The very same issues have had huge impacts on importing and logistics functions too. Whilst the world continues to open up, we are still feeling the effects of worldwide shortages of components and materials from all forms of industry.

We’re seeing builders having to plan several months ahead to ensure they have materials on site when they need them. Domestic builders are ordering windows and trusses long before the footings are even dug. Commercial builders are having to juggle trades and shuffle around access to try and keep the job on the critical path.

Traditionally we see partitions and ceiling contractors being the first trade to start on each floor on apartment projects, straight after the concrete floor slabs have been poured. They carry out the set out of the walls by marking out the position of walls and commonly installing the deflection head tracks that the studs will fix to before they frame up the walls. Many of these walls form fire rated compartments within the building including the apartments and service risers/cupboards.

Commonly we see the partitions and ceiling contractors come and frame and sheet the walls that will have pipes and cables pass through them first. This is because it is too hard to cut sheets of plasterboard neatly around pipes and cables if they have already been installed. Cutting the correct size hole for each set of pipes and cables is also critical to the passive fire aspects of treating these services to re-instate the fire rating after there has been holes cut in it. So running the plasterboard first is very important from a future safety aspect as well. This means that plasterboard is required on site before plumbers, electricians, fire and HVAC contractors can begin to carry out their works. So what happens when you don’t have the plasterboard? Simply put the job can be held up and in some cases stop until material is available.

So how else can builders keep the passive fire stopping aspects of a project moving ? They can use a multi-service transit such as the BOSS Fire Transit Box. The multi-service transit box is a passive fire rated product that can be installed up to the soffit before any framing or walls. It enables service trades to pass their pipes and cables straight through it. By using this method of treating the services from a fire rating perspective instead of traditional plasterboard, the critical path of the project can stay on track and services trades can get on the job sooner without any plasterboard. By using the box they can run services first and sheet later.

There are other bonuses too. Not only can the services trades be used on a project sooner, they can run their services easier and faster. By removing the bottom of the box, services can be lifted into position making installation simple. Normally plumbers and electricians would then also have to treat their services individually with passive fire products like sealants, fire collars and often in the case of metal services likely use thermal insulation wraps. Not only does this use up a lot of labour to install, but the risk of using the wrong products, or installing them incorrectly is a real issue the adds costly defects and hold ups of its own.

How does a fire box work you may ask? Well the transit is a metal outer chassis and contains sachets of BOSS Fire’s High Pressure Exerting Intumescent sealant known as ‘HPE’. In the event of a fire the intumescent expands and seals around the pipes and cables, closing and gaps as plastic pipes melt away. The unique BrushSeal design allows pipes and cables to simply ‘pass through’ without need for individually sealing cables or pipes or having to cut any other inserts. Significant amounts of fire testing to AS1530.4:2014 and AS4072.1-2005 has proven that the BOSS Fire Transit Box is also able to provide 60min and 90min Fire Resistance Ratings without any need for thermal wraps. In an apartment entry setting this saves significant amount of labour and material costs.

Builders are using innovations like the BOSS Fire Transit Box to navigate material shortages on site like plasterboard and getting many other added bonuses.

Posted in:The new range of drilling templates make assembling our suite of Aluminium partitions fast and simple without the need for any additional measurements.

For increased efficiency and accuracy the drilling templates are pre-measured at the required intervals.

This significantly reduces installation time by making it easier to use the Screw Flutes/Buddies.

There are 5 templates – one for each Aluminium Series and a key set for our Door systems.

Drilling templates available :

For more information please get in touch with your Account Manager or email us on info@potters.co.nz

Posted in:In a perfect world, architects, engineers and consultants will have had the time and resources to design a project from start to finish including how to treat all of the service penetrations so that builders and contractors can simply follow the plan. In reality with pressure from developers always pushing to shorten the design and build time often certain things are designed on the fly during construction.

A common aspect of design that we see often forgotten until well after works have begun is the firestopping of services where they pass through fire rated walls and floors. In the passive fire industry, it’s always much better to plan ahead and select a tested system that will be treating the penetration before cutting any apertures or running services. It’s great to see that most contractors these days are now conscious that when running their services that they need to select a fire rated product that has the relevant certification approved for the relevant type of pipes or cables. They are also far better these days understanding that the type of the wall or floor is also a critical element to the tested system.

But what about the size of the aperture? Does this matter? In short, yes. The size of the aperture is also an important part of the firestopping. A tested system will have been tested with a few key elements. The type of substrate, the type of pipe or cable (including quantity and size), the size of the opening and then the products that were used to treat the service and how they were installed.

Take for example a combustible PEX pipe commonly used for hot and cold water is often treated in fire rated walls using an intumescent sealant. These intumescent sealants are designed to expand in the event of a fire and crush inwards as the pipe melts away and essentially close the opening left by the melted pipe. The gap around the pipe will have been sealed in the test with a specific depth and width, and in some cases a surface fillet. The relationship between the amount of sealant and position of the sealant may impact on whether the sealant will in fact close the opening left by a melted pipe. Therefore it’s critical to understand a products testing and range of opening sizes relevant to the service.

expand in the event of a fire and crush inwards as the pipe melts away and essentially close the opening left by the melted pipe. The gap around the pipe will have been sealed in the test with a specific depth and width, and in some cases a surface fillet. The relationship between the amount of sealant and position of the sealant may impact on whether the sealant will in fact close the opening left by a melted pipe. Therefore it’s critical to understand a products testing and range of opening sizes relevant to the service.

BOSS FireMastic-HPE is a high pressure exerting intumescent fire rated sealant that is used for a variety of plumbing, electrical and HVAC services. Recently the FireMastic-HPE has carried out further testing on PEX pipes highlighting consistent performance with annular gaps from 5mm up to 20mm. It also carries testing where the pipe is offset in the aperture.

So what about oversize apertures? It’s all well and good to cut a nice core hole for a pipe, but what about larger services like cable trays, cable bundles or even a mixture of trades?

That’s where BOSS Fire has a wide range of passive fire products to suit your services passing through a variety of different apertures.

BOSS FirePillows-240 are a cost-effective fire barrier that be used to tightly pack in around non-combustible services like cables and cable trays, or metal pipes. They are best suited to concrete and masonry walls or concrete floor slabs and offer up to a 3hr fire rating.

BOSS FirePillows-240 are a cost-effective fire barrier that be used to tightly pack in around non-combustible services like cables and cable trays, or metal pipes. They are best suited to concrete and masonry walls or concrete floor slabs and offer up to a 3hr fire rating.

BOSS Batts offer another solution for oversized apertures. BOSS Batts consist of a high density mineral fibre batt with an ablative fire resistance coating. They offer excellent flexibility in how that can be installed around a pre-existing service or be friction fitted into an aperture to act as a substrate for other passive fire products such as collars or mastics.

BOSS FireMortar-360 is another passive fire product used to re-instate a fire rating in fire rated walls and floors. Offering a trowelable or pourable system it also offers load bearing capabilities.

Another product which offers new build or retrofit options is the Multi Award winning BOSS Fire® Transit Box which is revolutionising firestopping methods for large bundles of mixed services. Designed to allow large bundles of pipes and cables to all pass through one single fire rated enclosure, the Transit Box is the only tested and proven method of firestopping multiple services with such simplicity of installation and ease of compliance. Not only does it come in a wide range of sizes to suit a variety of apertures, it also carries approvals with BOSS Batts so that multiple boxes can be installed in different aperture sizes.

When it comes to planning your firestopping systems, always take into consideration the approved aperture size and select the appropriate products to suit.

Posted in:Fire protection is a critical life safety aspect of any building. Whilst the building industry is getting far better at understanding what goes into the passive fire protection, unfortunately this critical part of a building is often left up to services trades to deal with as part of their installation package.

This means that it’s often the plumber who might be responsible for the correct fire treatment of their pipes where they pass through a fire rated wall. Or an electrician is responsible for the correct product selection and installation of a product to treat their cables where they pass through a fire rated floor. To become a qualified electrician or plumber the person will have carried out several years of training before being able to sign off their works on a building site. Whilst services trades are masters at their key profession, it is all too common that they haven’t undergone any formal training on the passive fire aspects of the job site.

Treating service penetrations correctly can get complicated quickly. There are many aspects that go into an approved tested passive fire protection system.

Key factors that go into a system include:

Only once these are known can a contractor begin to select the correct product or system that will perform in the desired manner. Noting that a system may include several different products that each have specific installation requirements.

On new builds it’s can be easier to plan the correct size opening for the service and the correct products on hand. But what about when there is small remedial works? Or when someone has run a conduit or a small bunch of cable through a wall that they didn’t realise was fire rated until after they’d already made a hole and run a pipe through it? Fire rated sealants often require a very specific amount of sealant to be installed around a service to a required depth. Fire collars will call for a different size collar to suit every diameter size of each pipe. Will the contractor have the perfect size hole for the cable to suit the tested sealant application? Will the contractor have a full range of fire collars in the van ready to put on the pipe? Unlikely.

That’s where products like the PenoPatch by BOSS Fire can be a handy product to have in the ute or van. Designed for 1hr fire rated walls the PenoPatch is known as “The 30 second fire seal” because it only takes 30 seconds to install and makes for a quick and easy installation for even the most novice tradesman. The putty discs come in a carton of 20, small and easy to store in the van for whenever the need arises. To apply simply remove the backing paper, put the slot over the cables or pipe, and stick to the wall molding the disc around the service. The 60mm PenoPatch is designed for 20mm apertures, or the larger 100mm PenoPatch is designed for up to 50mm apertures.

All fire protection should have the proper due diligence it deserves, and careful consideration should be taken before installing any fire product, however starting with products that have a wide versatile certification range will certainly give any trade a head start.

BOSS Fire uncomplicate the complicated. They innovate for user-friendly, versatile products that eliminate the installation risk and heavily reduce labour costs. The Senior Team all have trade, technical or engineering backgrounds so they know first-hand the pressure on designers, contractors, and certifiers to ‘get it right’. Their way of thinking like an installer sets them apart, borne from decades ‘on-the-tools’. So, when they test & develop systems, they do so to ensure class leading levels of fire protection, and to simplify the construction process by making the systems faster & easier to select and install.

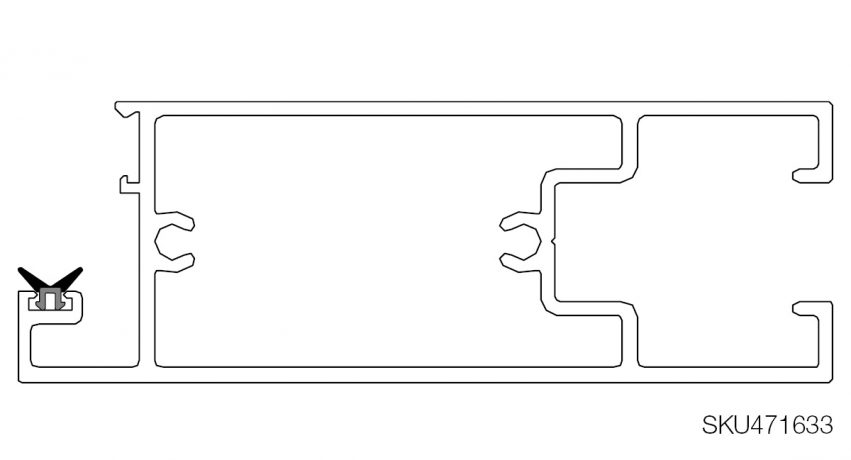

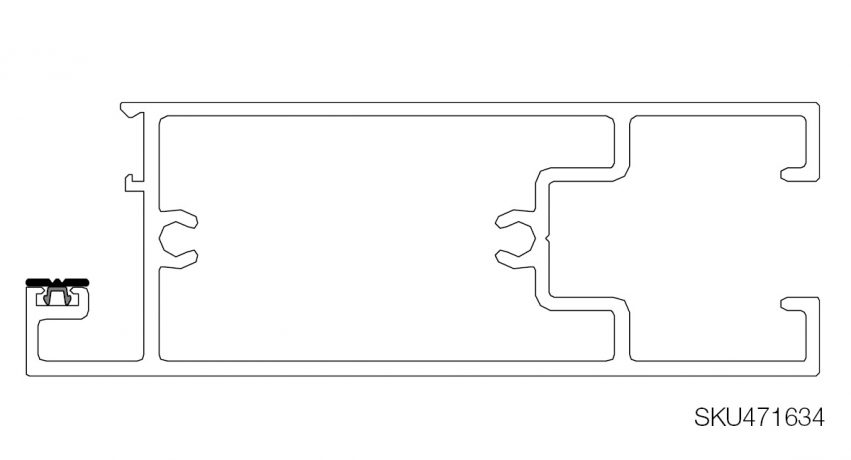

Posted in:Free quick reference Aluminium flip chart

In conjunction with our Aluminium Specifiers manual, we have now released an updated Aluminium Partition Flipchart.

An industry-leading quick reference guide outlining each of the profiles contained within our Aluminium Suites.

Get in touch on specsupport@potters.co.nz if you would like a hard copy delivered, or download the flipchart below.

Posted in:Potter Interior Systems proudly supplied a range of quality products and proven solutions for Southern Cross Healthcare, which has recently been nominated as a Finalist in the Best Design Awards 2021.

Sprawled across two stunning floors and housing over 600 staff, the new workspace prioritises staff health and wellbeing, with a design focus on efficient and mobile ways of working.

This gives staff the freedom to choose their work environment, based on the space that best suits their performance or personal preference.

Ceiling panels can play a large role in treating office acoustics and Potters’ AMF Thermatex Acoustic panels were selected for their high levels of sound optimisation. Thermatex Acoustic is a 19mm thick suspended ceiling tile made from a specially perforated mineral board that features an acoustic fleece facing. The perforations provide excellent sound absorption while the fleece offers a smooth, elegant surface finish. The combination of high density, bio-soluble mineral wool with clay and starch provides excellent physical characteristics, particularly for acoustic performance.

All of Potters’ AMF Thermatex Acoustic Range are Red List free giving confidence that these products are non-toxic and safe and maintain GreenTag’s GreenRate Level A certification.

Level A products achieve a ‘Sustainability factor’ of 100% ensuring healthy and ethically sourced products are used.

While open areas hold the key to collaborative working, the need for privacy in confidential meeting spaces while still allowing visual connectivity was paramount. As specialists in aluminium partition systems, Potter Interior Systems offered a host of design options and configurations. C Series 45 Aluminium Partitions were paired with DS Doors + Sliders finished in a customised ‘Karaka Green’ to complement the natural surrounds.

All Potter Interior Systems aluminium partition suites are designed and produced in New Zealand, proudly carry the Declare label and are Red List free.

Posted in:The Potter Interior Systems range of perforated plasterboard allows architects and designers to create beautiful ceilings and walls with high levels of acoustic performance.

The panel perforations together with acoustic fabric lining and insulation, where used, reduce echo and noise reverberation to create more comfortable environments for work and leisure.

Developed by worldwide plasterboard specialist, Saint-Gobain. These products also feature innovative Activ’Air technology to help improve indoor air quality.

Potter Interior Systems has developed exclusive relationships with leading manufacturers to offer the widest selection of high quality plasterboards to meet a range of performance

requirements.

The versatile range features:

• Five Rigitone options with edge to edge pattern layouts for a monolithic, seamless design

• Three Protone contemporary grid-style patterns for exceptional acoustic performance

• Gyprock Standard 6mm Round has a traditional pattern layout with economical sound attenuation

Download our new catalogue here

Posted in:In recent years the residential construction sector has seen continued growth. This growth has had widespread repercussions that include both significant innovation and new challenges. As complex construction materials and technologies witness growing use, residents of multi-residential developments are demanding more services within their living space. Coupled with strong developer interest in increasing the lettable area, the question of passive fire compliance has become increasingly complex.

As a result, the industry now more closely scrutinises trades and subtrades, many of which are commonly falling short of compliance requirements relating to the fire rating of multi-residential apartments. This in turn extends deadlines and significantly increases project costs. Throughout the industry, there is growing awareness of the risk of incorrect or inadequate fire separation, and builders and trades are accordingly growing more responsible and seeking innovative, effective and reliable solutions for passive fire protection.

Let’s explore the key barriers to achieving compliant fire ratings on large buildings – particularly high-rise apartments – in today’s construction climate and look at an alternative method to overcome these.

Understanding The Problem

In the past, the major construction trades (being electrical, air conditioning, plumbing, data, fire, and internet) often applied their own passive fire protection after installing their services.

Whilst many builders use a Passive Specialist Applicator (a specialist trade that fire rates other trades’ penetrations) in the interests of costs and externalising risks – it’s also common for many subtrades accountable for the passive fire rating of their own work. This may provide a perceived shift of responsibility away from the builder, but it also poses a significant risk in terms of ensuring the adequacy of fire rating. ‘Approved’ systems can fail due to incorrect product specification or failure by the installer to follow strict installation guidelines.

Installation error is a major threat to passive fire protection since it is difficult to monitor the work methods of every subtrade. Depending on the varying skills levels of each installer, there is always a possibility that the subtrade will misinterpret installation guidelines, particularly where the fire rating system is complex or unfamiliar. Difficult installation contexts are becoming increasingly common, particularly in high-density apartments where space above the ceiling is at a premium.

As a consequence of developers seeking to maximise lettable area, the ceiling space height in multi-residential developments is often decreasing, while the complexity of technical services into each apartment is increasing – thereby further complicating the whole firestopping challenge. Without destructive inspections, it’s difficult to identify a passive detail after installation as physical aspects are not visible.

In addition to physical complications, the number of materials that must be protected within the tight confines of today’s multi-residential apartments is increasing. Residents now expect more services than ever in their living spaces, many of which use multiple cables and pipes, and trades must now engage with the latest in pipe material innovation and the myriad of plastics used for different pipe applications (such as PEX, PEX-AL, PP, PP-R, HDPE, uPVC, cPVC, and more) as well as mechanical bundles that include paircoil, cables, and lagged or unlagged metal pipes.

When it comes to cable types, the possibilities feel endless, and the ‘Standard Configuration’ becomes hard to work to when all the possible variables, sizes and quantities are considered.

Unfortunately, the vast majority of fire rating technology available does little to simplify the product selection process, and the impracticality of understanding all tested systems on the market makes it difficult correctly install one hundred percent of the time.

How The Industry Has Responded

Growing concerns regarding fire safety have also prompted a general movement in the industry toward investigating new, innovative fire rating technologies. In conjunction with the rising popularity of multi-residential apartments, these concerns mean that industry now seeks solutions that can bundle multiple services in tight spaces and at the same time reduce the risk of installation error.

In short, the industry needs fire rating solutions that ensure compliance, reduce cost, and eliminate the risks.

Innovative Tested Solution

In response to growing demand for fire rating technologies that overcome the challenges typically associated with passive installation, BOSS Passive Fire developed the BOSS Fire Transit Box which is revolutionising methods used to firestop services into apartments and units in residential buildings. The Multi-Service Pipe & Cable Transit lowers overall build cost, simplifies the installation process & eliminates risk involved with other life safety passive fire practices to achieve building compliance.

BOSS’s game changing Fire Transit Box “bundles” services into a single solution providing building code compliant, AS1530.4:2014 and AS4072.1-2005 with an FRR of up to -/120/120 on the widest range of services. 30min, 60min and 90min configurations are also widely tested and approved.

The unique design comprised of a steel chassis, industry-leading HPE expanding intumescent and an innovative BrushSeal™ that allows trades to simply “pass through” pipes and cables in one small compact product. There’s no need to individually treat pipes and cables with traditional sealants, wraps, collars and backing rods.

The BOSS Fire Transit Box can be installed before any walls are constructed – often fixed into place by the first trade onto a newly formed floor, such as the dry wall partition installer or fire sprinkler contractor. This makes scheduling a breeze, removing the traditional requirements that dictate the order of process amongst trades.

Independent contractor assessments estimate the the BOSS Fire Transit Box reduces up to 90% of labour costs compared to traditional methods, and significantly reduces overall build time and cost. Beyond this, the BOSS Fire Transit Box virtually eliminates any scope for error. Services trades then simply slide their pipes and cables through the box and get on with what they do best – their trade. In most applications, there is no need for any additional thermal wrap, as the BOSS Fire Transit Box meets all the requirements of AS1530.4, AS4072.1 and the NZBC.

The mounting method for services is exactly the same as that for a non-rated wall, and removes the possibility of installation error due to poor workmanship, incorrect product selection, or misunderstood instructions. Where other methods of passive fire protection are accompanied by complex or hard to interpret instructions, the straightforward installation of BOSS Fire Transit Box leaves little room for mistake.

This single, streamlined product ensures compliance at the time of installation meaning project sign-off its simple and transparent. And with periodic checks made just as easy, the ongoing inspection requirements of AS1851 (Maintenance of Fire Protection Systems and Equipment) are significantly streamlined.

A single BOSS Fire Transit Box can house all of the common apartments and riser services commonly seen in modern construction. PEX & PEX-AL water and gas pipes, lagged and unlagged copper pipes, steel and cPVC Sprinkler pipes, along with all the common power and comms cables and conduits like orange circular sub mains, CAT5e, CAT6, fire alarm, intercom, security, COAX and NBN to name a few.

In addition to its unique performance and low-fuss installation, the BOSS Fire Transit Box is also acoustic rated to Rw50, making it ideal for minimising noise travel in high density apartment construction and meeting the requirements for apartments contained the building code requirements.

The multi award-winning BOSS Fire Transit Box was first recognised in 2017 at the Australian Fire Protection Association ‘Industry Awards’ which named Multiplex’s luxury Capitol Grand the winner of the prestigious ‘Project of the Year’ award for adopting the use of the product. Since then, it has been awarded ‘Product Innovation of the Year Award’ at the 2018 edition of the annual Australian Construction Awards. Most recently in October 2021, the BOSS Fire Transit Box won two ‘Good Design Awards’ for Product Design and Engineering Design.

Posted in:By involving Potter Interior Systems early in the design stage, architects can ensure the product specified is approved for the application and to the applicable standards.

A common problem we find in the industry is a lack of formal training on fire ratings or passive fire. Many of the key factors that make for a compliant system when passing services through fire rated compartments such as walls and floors are not fully understood. Unfortunately, this leads to the wrong product being installed and it’s all too common that this isn’t identified until the project is ready for handover and access to fix something is often near impossible or at least more difficult than it was to originally build. This leads to cost blow outs.

Just because a product says that it’s ‘fire rated’ doesn’t mean that it has the required fire resistance rating (FRR) that’s relevant to the applicable Standard or to the Building Code, nor does it mean it can be used for all applications across a building.

We commonly see electrical, plumbing and HVAC trades miss critical details or make assumptions on how a product was tested or approved in relation to their planned use of the product. For example, because a product is tested with cables in a concrete wall, doesn’t mean it’s approved for cables in a concrete floor slab.

Often there are a lot of assumptions made with sealants too. For instance, a sealant might be used on a bundle of 50 power cables, but it’s only been approved for a bundle of say ten comms cables. Sometimes it’s as simple as the size or dimension or that the sealant was applied was different to how it was tested or approved.

With metal pipes we see the thermal insulation wrap often forgotten which is required due to the way the metal transfers heat from one fire compartment to the next (i.e. overlooking the insulation criteria of the fire rating).

The best result will be achieved by involving the supplier early in the design stage of each project. They can run-through a set of questions that will help identify the correct compliant fire stopping solutions.

Most importantly, they will help to ascertain that the product specified is approved for their application and to the applicable standards. We need to ensure that the products planned for use have been tested or approved to AS1530.4 and AS4072.1 by a NATA approved laboratory in accordance with their actual proposed application.

Key things about the requirements that should be matched to the proposed certification would be:

This type of information all relates to the certification on how a product or system has been approved for use in the first place. We then need to consider how to install the products or systems on site in the same manner they were approved.

As the NZ distributor of BOSS Passive Fire products, Potter Interiors stock a range of cutting-edge firestopping systems for the commercial construction industry. The highly experienced team at BOSS innovates to make passive protection requirements easier to comply with.

Their wide range of products are uncomplicated, simple to install, and lower the overall costs of compliance. What’s most exciting and unique to BOSS Fire is products like the PenoPatch, the BOSS Fire Transit Box and FireMastic-HPE.

The BOSS Fire Transit Box has been the dubbed The GameChanger as it’s revolutionising passive fire. It consists of a single transit box (available in a number of sizes) that can be used to firestop large bundles of mixed services. By having the freedom to mix and match plumbing, electrical and HVAC services using only one firestopping method, the risk of using the wrong product is heavily reduced. It’s extremely versatile in the form of the amount of certified substrates and offers new build and retrofit options.

Once the box is sealed to the substrate electricians and other trades alike simply ‘pass through’ their cables or services. This is due to the unique brushseals on each open end. No need for sealing individual bundles of cables or conduits. In a fire scenario the box has internal high performance intumescent that expands in a fire scenario closing off the box offering up to a 2 hour fire rating.

The PenoPatch is a small putty disc that is approved for small cable bundles and conduits. It only takes 30 seconds to install and provides a 1 hour fire rating. It’s incredibly cost effective and it’s easy to keep a small box in the van for a ready to go, no mess application.

The Potters range of trusted and well known BOSS sealants including the market leading 5 hour fire rated FireMastic-300 for gaps in walls and floors, also allows for a significant number of metal pipe and cable penetrations. A prime example of simplifying a system is the FM300 can be used on a 60mm diameter sprinkler pipe and doesn’t need any thermal wrap.

The flagship high pressure exerting intumescent sealant that expands up to 40x in a fire scenario known as FireMastic-HPE. These are suitable for new builds and have a number of retrofitting options. FireMastic-HPE offers market leading solutions for HVAC bundles and can even retrospectively protect conduits passing through walls where fire stopping has been completely overlooked and provide a surface mounted protection method.

Contact Potters’ Technical Team to discuss your application or visit the Potters website for detailed technical information to help select the right product for the right application.

Posted in:With its innovative features our Soho Series of Aluminium partitions are an incredibly practical way to achieve an industrial style glazing look, in a fraction of the time.

The light-weight, cost effective alternative is easier to fabricate and install than traditional glazing, while refusing to compromise on its stunning industrial-inspired aesthetics.

Being extremely versatile the Soho series features five profiles in total, capable of combining with our other suites to deliver unique solutions for the office that’s on trend.

The lightweight aluminium is attached to the glazing with industrial strength adhesive and can be positioned onto the glazing panel in a variety of ways. You are only limited by your imagination!

The Soho Series consist of two 35mm options; A-Frame Bars and Flat Bars, both of which are intended to complement the visual appeal of our Aluminium Partition Suites and Doors.

Soho is designed to provide an artistic feel to the suites and are not necessary to strengthen the structure of the partitioning in situ.

All Potter Interior Systems aluminium partition suites are proudly designed and produced in New Zealand, carry the Declare label and offer a 10 year performance warranty.

From aesthetics to performance our expertise in developing custom aluminium profiles sets us apart.

Get in touch today with the specification team at specsupport@potters.co.nz

Posted in:Streamline your order processes and save time with CSR Connect.

View Pricing

View customised product pricing based on your account.

Order Products

Real time product search and online ordering.

Invoices/Statements

Search the central document hub for invoices, credits and statements.

Analyse Purchase History

View and compare recent purchases and product history.

Registration is free and it only takes 60 seconds to get started.

For further information, we invite you to contact your account manager.

All orders placed will be shipped once NZ reaches Alert Level 3.

Potter Interior Systems has developed exclusive relationships with leading manufacturers to offer the widest selection of high quality plasterboards to meet a range of performance requirements.

We are excited to announce the release of our new 24 page product catalogue outlining our versatile range which includes:

Wherever healthcare facilities are built or modernised, they create a challenge for clients, architects and planners. Strict hygiene regulations must be observed, while the building must be functional and aesthetically attractive.

The selection of the optimum ceiling system depends on the use of the room. Whilst hygiene is of paramount importance in operating theatres and intensive care units, sound protection and room acoustics are needed in corridors and foyers. In sanitary areas and kitchens, the ceiling also needs to withstand high humidity.

Clean Room – ISO Classification

Clean rooms are essential for medical research and treatment. They enable different parameters, such as bacteria, temperature, humidity and pressure to be exactly controlled. The air purity classification according to DIN EN ISO 14644 is the most well-known standard. It states the maximum number of particles in the ambient air and divides the cleanrooms into classes from ISO 1 to ISO 9, with class 1 being the highest specification for air purity.

AMF Thermaclean S The Solution for Hygiene Environments

Specifically developed and tested for use in sensitive areas of health care facilities to meet the strictest of hygiene requirements. The vinyl laminated tiles feature a preventive effect against germs and the accumulation of pathogens, bacteria and fungi. Perfect for hard-working environments as they are robust, disinfectant-resistant, low maintenance and easy to clean.

Specialist Hygiene Features Include

Get in touch with Potters’ specification team today to assist with creating solutions for your next Healthcare project at specsupport@potters.co.nz

Posted in:Free Puffer Vest with every 50 Tracklok, Gridlok or Deflok items purchased between July To September 2021 🔥

*Reward valid from 1st July to 31 September.

Exclusive to Potter Interior Systems trade account holders.

Tracklok products include Retro, Timba, Flat, Gaplok, Deflok and Gridlok.

Limited stock of puffer vest available, while stocks last. Limit ten per customer.

Potter Interior Systems Standard Terms and Conditions of Sale apply.

View the Tracklok range here

Posted in:Pro-Fit V Backing Seal

Pro-Fit Flat Backing Seal

The project, designed by Athfield Architects Ltd, took out top honours in the Greenstone Group Education Property Award in the 2021 Property Council of New Zealand Industry Awards.

The Potter Interior Systems specification team, working with Athfield Architects met the brief of ‘A modern school with a rich past’, incorporating modern learning environments while still maintaining its heritage listing.

The new block includes contemporary learning spaces, formal study areas, break out rooms and specialist music facilities. The 21 teaching spaces around the block are designed with flexibility in mind, allowing for open-plan learning spaces or a return to traditional classrooms if required.

Potter Interior Systems proudly supplied Rigitone Matrix 8mm Round in the entrance ways and communal areas. Its sophisticated look is universally appealing and highly functional for public areas in commercial buildings. Its acoustic control is achieved through a combination of perforated patterns and a highly effective fabric backing which prevents dust from the ceiling entering the room while also masking the ceiling framework.

Architects and specifiers are actively seeking solutions to improve air quality by reducing the levels of VOCs and other harmful pollutants. Rigitone Plasterboard is manufactured with Activ’Air technology — a unique process that converts formaldehyde into non-harmful compounds that are locked in the board and can’t be released back into the air.

While open areas hold the key in collaborative working, the need for classrooms to be easily closed off was also paramount. As specialists in aluminium partition systems, Potter Interior Systems offered a host of design options and configurations. A seamless mix of DS Series aluminium partitions with doors and sliders were specified in a natural anodized finish that complement the natural timber surrounds.

All Potter Interior Systems aluminium partition suites are designed and produced in

New Zealand, proudly carry the Declare label and are Red List free. From aesthetics to performance for all commercial interior needs, the team at Potter’s can support the specification of the perfect solution.

Architect: Athfield Architects

Construction: RDT (Project Management) + Southbase Construction

Photography: Lightforge Photography

Awards: Winner – 2021 Local Awards by New Zealand Institute of Architects – Education Category

Grand Prize

Ford Ranger FX4 Valued Up To $56,000

Second Prize

SeaDoo GTI130 Valued Up To $21,000

Third Prize

Luxury Spa Pool Valued Up To $9,995

Bonus Prizes

One Winner Each Month Per Branch Valued Up To $700

Entries is open Monday 01 June, 7am to Tuesday 30 November, 12pm 2021.

Winners will be announced Friday 10 December, 8am.

Visit www.clubpotters.co.nz to enter

Posted in:Potter Interior Systems proudly supplied the Austratus Ceiling + Wall Timber Batten system to the Greater Wellington Regional Council at 100 Cuba Street, Wellington.

As one of the largest open-plan commercial spaces in Wellington, the Cuba Street Farmers heritage building has been transformed into a state-of-the-art workspace and nominated as a finalist in this year’s Property Council New Zealand Industry Awards in both the Commercial Office and Heritage and Adaptive Reuses award categories.

The Potter Interior Systems specification team, working with Athfield Architects, met the brief with the Austratus Ceiling + Wall Timber Batten System, specified in Square Fin Combo and finished in Western Red Cedar. The system was specifically chosen for its timeless appeal and ability to blend seamlessly with existing heritage features throughout.

When it comes to inspiring spaces, nothing makes an impact quite like an architectural timber ceiling, wall or screen. Colour, warmth, tone and texture — timber has a unique, sophisticated appeal.

To align with wider sustainability goals of specifying products that eliminate impact on the environment, designers and builders can specify the Western Red Cedar, Hemlock and New Zealand Pine products with confidence. The range has PEFC Certification (the world’s largest forest certification system) to ensure timbers are sourced from sustainably managed and controlled forests.

Architect: Athfield Architects

Construction: LT McGuiness

Ceilings + Wall Panels Installed By: NZ Ceilings