By involving Potter Interior Systems early in the design stage, architects can ensure the product specified is approved for the application and to the applicable standards.

A common problem we find in the industry is a lack of formal training on fire ratings or passive fire. Many of the key factors that make for a compliant system when passing services through fire rated compartments such as walls and floors are not fully understood. Unfortunately, this leads to the wrong product being installed and it’s all too common that this isn’t identified until the project is ready for handover and access to fix something is often near impossible or at least more difficult than it was to originally build. This leads to cost blow outs.

Just because a product says that it’s ‘fire rated’ doesn’t mean that it has the required fire resistance rating (FRR) that’s relevant to the applicable Standard or to the Building Code, nor does it mean it can be used for all applications across a building.

We commonly see electrical, plumbing and HVAC trades miss critical details or make assumptions on how a product was tested or approved in relation to their planned use of the product. For example, because a product is tested with cables in a concrete wall, doesn’t mean it’s approved for cables in a concrete floor slab.

Often there are a lot of assumptions made with sealants too. For instance, a sealant might be used on a bundle of 50 power cables, but it’s only been approved for a bundle of say ten comms cables. Sometimes it’s as simple as the size or dimension or that the sealant was applied was different to how it was tested or approved.

With metal pipes we see the thermal insulation wrap often forgotten which is required due to the way the metal transfers heat from one fire compartment to the next (i.e. overlooking the insulation criteria of the fire rating).

So how can we avoid these mistakes?

The best result will be achieved by involving the supplier early in the design stage of each project. They can run-through a set of questions that will help identify the correct compliant fire stopping solutions.

Most importantly, they will help to ascertain that the product specified is approved for their application and to the applicable standards. We need to ensure that the products planned for use have been tested or approved to AS1530.4 and AS4072.1 by a NATA approved laboratory in accordance with their actual proposed application.

Key things about the requirements that should be matched to the proposed certification would be:

- Service type: What type of cables are used, what size are they and how many are there? Or what is the pipe made from and what diameter is it?

- Substrate material and thickness: What is the substrate that the service is passing through? Eg: A 150mm thick concrete floor slab or a 116mm thick double layer fire rated plasterboard wall?

- Size of opening or aperture: What is the size of the opening you need to seal? Eg: 600 x 400mm or 20mm diameter round hole.

- Fire rating: What is the FRR required? Eg: 2 Hours or FRR -/120/120.

This type of information all relates to the certification on how a product or system has been approved for use in the first place. We then need to consider how to install the products or systems on site in the same manner they were approved.

As the NZ distributor of BOSS Passive Fire products, Potter Interiors stock a range of cutting-edge firestopping systems for the commercial construction industry. The highly experienced team at BOSS innovates to make passive protection requirements easier to comply with.

Their wide range of products are uncomplicated, simple to install, and lower the overall costs of compliance. What’s most exciting and unique to BOSS Fire is products like the PenoPatch, the BOSS Fire Transit Box and FireMastic-HPE.

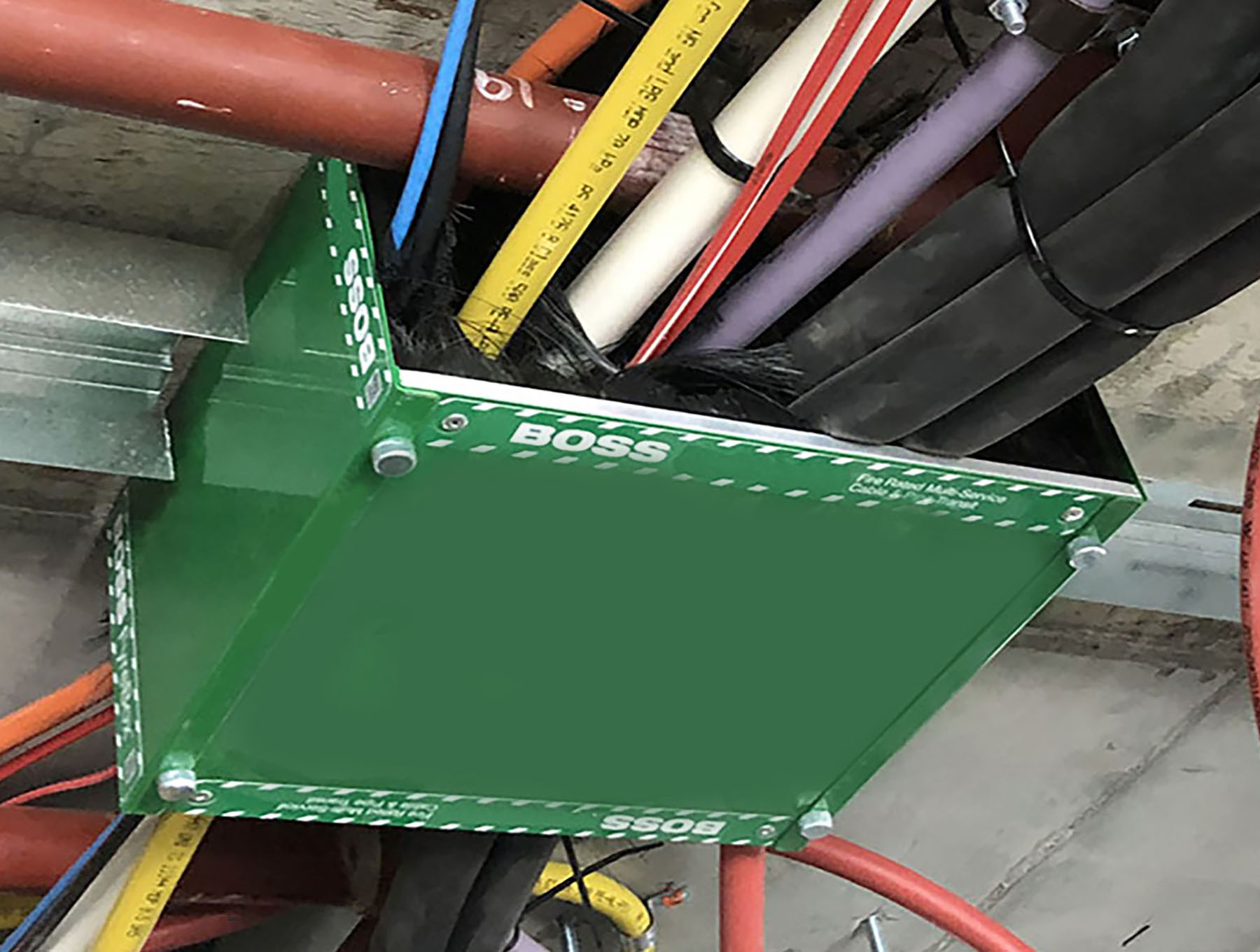

The BOSS Fire Transit Box has been the dubbed The GameChanger as it’s revolutionising passive fire. It consists of a single transit box (available in a number of sizes) that can be used to firestop large bundles of mixed services. By having the freedom to mix and match plumbing, electrical and HVAC services using only one firestopping method, the risk of using the wrong product is heavily reduced. It’s extremely versatile in the form of the amount of certified substrates and offers new build and retrofit options.

Once the box is sealed to the substrate electricians and other trades alike simply ‘pass through’ their cables or services. This is due to the unique brushseals on each open end. No need for sealing individual bundles of cables or conduits. In a fire scenario the box has internal high performance intumescent that expands in a fire scenario closing off the box offering up to a 2 hour fire rating.

The PenoPatch is a small putty disc that is approved for small cable bundles and conduits. It only takes 30 seconds to install and provides a 1 hour fire rating. It’s incredibly cost effective and it’s easy to keep a small box in the van for a ready to go, no mess application.

The Potters range of trusted and well known BOSS sealants including the market leading 5 hour fire rated FireMastic-300 for gaps in walls and floors, also allows for a significant number of metal pipe and cable penetrations. A prime example of simplifying a system is the FM300 can be used on a 60mm diameter sprinkler pipe and doesn’t need any thermal wrap.

The flagship high pressure exerting intumescent sealant that expands up to 40x in a fire scenario known as FireMastic-HPE. These are suitable for new builds and have a number of retrofitting options. FireMastic-HPE offers market leading solutions for HVAC bundles and can even retrospectively protect conduits passing through walls where fire stopping has been completely overlooked and provide a surface mounted protection method.

Contact Potters’ Technical Team to discuss your application or visit the Potters website for detailed technical information to help select the right product for the right application.