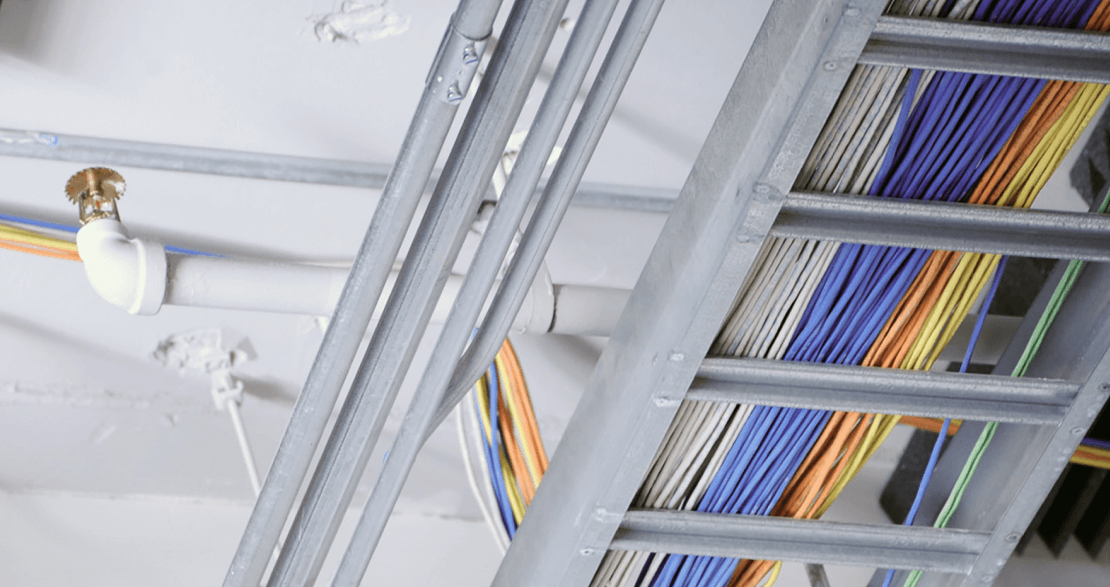

In commercial construction, fire safety is a critical design priority. That’s why designers and contractors across New Zealand rely on...

Know Your Fire Standards

What is a Fire Resistance Rating or FRR?

We have all heard the terms Fire Rated, Fire Resistant and Fire Retardant. But do they all mean the same thing? Whilst the words themselves sound similar, and when looking at a dictionary definition, they might sound the same, however…

Read MoreLatest Articles

Potter offer a wide range of global products with versatile and unique designs that are suitable for a range of projects.

New Release: Aluminium Profile Flip Chart We’re excited to announce the launch of our updated Aluminium Systems Suite Overview Flip Chart –...

The transformation of the QBE offices in the landmark 125 Queen Street building, Auckland used a range of materials available...

Whiteboards are key to nearly every office and learning space. No matter the technology progression, nothing can quite.

As one of the leading manufacturers of whiteboards for the commercial construction market throughout New Zealand

First released by the Ministry in partnership with the Building Research Association of New Zealand (BRANZ) in 2007 and the...

This year TRACKLOK Ltd turns 10 years old! What a ride and what an accomplishment — they have taken the...

Whiteboards are arguably one of the most iconic tools associated with education and research suggests that students have a higher...

Wherever healthcare facilities are built or modernised, they create a challenge for clients, architects and planners.